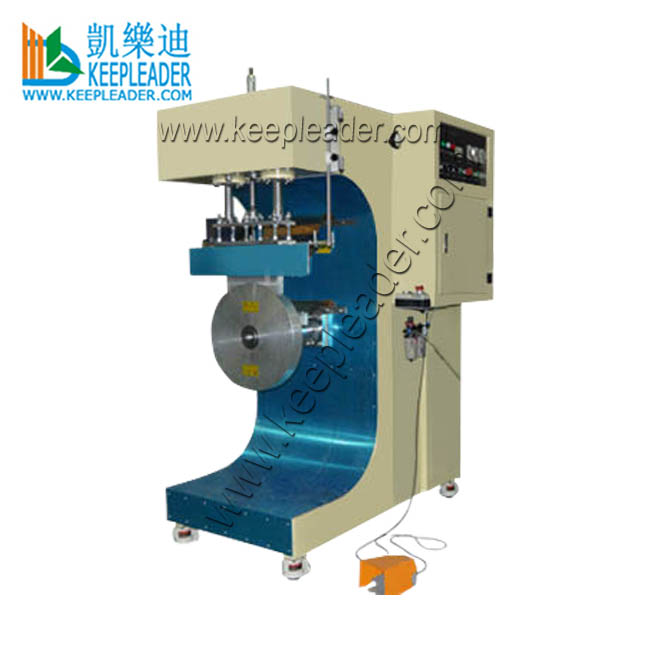

Membrane Sealing High Frequency Curved Welding Machine for PVC Tent_Tarpaulin_Canvas HF/RF Welder of Truck Cover HF Welding

Membrane Sealing High Frequency Curve Welding Machine

01: Application

Membrane Sealing High Frequency Curve Welding Machine has exceptional design of curved upper electrode and rotary bottom electrode of disked shape for round seam sealing, intermingled material of membrane structured Tarpaulin, Tents, Tensile fabrics, PVC, PU, TPU film to make bags, oil booms, truck covers, swimming pool lines and covers, airline hangars, large billboards, fast doors, side curtains, inflatable products, sunshades cloth, because of Curved pressed during dielectric heating in HF welding, this Membrane Sealing High Frequency Curve Welding Machine is suitable for round shaped line sealing, the bottom electrode is rotary disk design for manual feeding, this HF welding machine can be fitted with special impulse electrode for welding non-HF weld able fabrics made of PE and, PP, Curved HF electrodes for sealing round profiles made of PVC and any other required thermoplastic membrane structure precision HF welding

02: Parameter

|

Name |

|

|

Model |

KLR-8KWC |

|

HF Power |

8kw |

|

Power Input |

15KVA |

|

Voltage |

AC380V / 3P or AC 220V / 3P |

|

Frequency |

27.12MHz |

|

Driven Mode |

Pneumatic |

|

Max Pressure |

800kgs |

|

Stroke |

200mm |

|

Upper Electrode |

Curved Electrode, 36mm Width |

|

Lower Electrode |

Diameter 450mm Disk, also optional |

|

Oscillation Tube |

7T69RB |

|

Heating Time |

1~10 S, adjustable |

|

Gross Weight |

800kgs |

|

Net Weight |

980kgs |

|

Dimension |

1300*780*2200mm |

03: Character

The HF Welding is designed for curved welding in manually rotary feeding

Welding Bar and lower electrode/round disk can be made basing on individual demanding

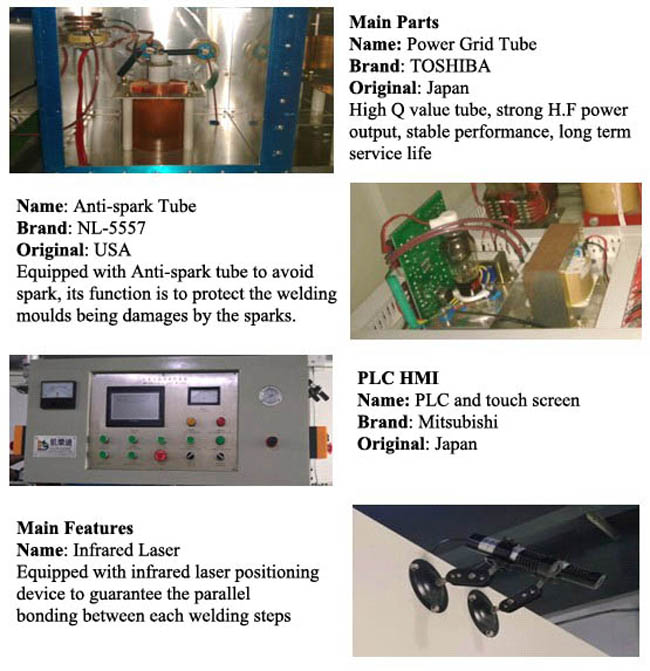

High Sensitive Anti-spark device to protect the welding electrode and article

Operation panel can be freestanding, front or side mounted

European standard square high frequency vibration cavity is more reliable

High frequency Power scale: 5kw~35kw according to different welding size and material

Convenient welding for curved inflatable boats, water bladder, PVC tubes at its round shaped seam

Sturdy Steel plate structure for high pressure in stable performance

Ideal for domestic and industrial articles

Gives mass and fast welding even with domestic power with low rate of power consumption

No warm up period is required

All controls are visible and easy to operate during the welding performance

Practical functionality with precision HF welding head

Sealing efficiency from 1kw: 40cm2 for standard PVC material

Universal usage for PVC, PU, TPU reinforce electrode

PP, PE weld ability with optional impulse electrode

Membrane Sealing High Frequency Curved Welding Machine equipped with Curved upper electrode and bottom round disk for curved welding

Membrane Sealing High Frequency Curve Welding Machine also have other advanced compoments, if you cannot find your aimed parts, please confirm

Membrane Sealing High Frequency Curved Welding Machine has exceptional design for curved welding profile made of PVC, PU,TPU tank

Membrane Sealing High Frequency Curved Welding Machine

01: Working Principle

Membrane Sealing High Frequency Curved Welding Machine works with thermoplastic membrane structure that has a high dielectric constant, in this welding process, an electric field is produced near the overlap, the positive and negative pole of which is alternated approximately twenty-seven million times per second, every time the electric field changes, the dipole molecules of the polymer attempt to align around to realign themselves to the new field orientation, because this movement of membrane molecules are impaired by inertia and friction, the molecules don’t flip in unison, this constant relative movement of the molecules results in intermolecular friction with results in inside heat and, subsequently, melting, high frequency/radio frequency membrane welding typically has weld cycle times from two to five seconds, and can handle the thickness of membrane sheet 1.5mm

02: Welding ranges

Some membrane structure plastic are more of a challenge to Membrane Sealing High Frequency Curved Welding Machine that others and may even require a special process, No matter the level of difficulty, KEEPLEADER Technologies is confined in its ability to expertly perform High frequency/HF/RF welding on the following thermoplastic membrane structure

021: Polyvinyl Chloride (PVC

022: Thermoplastic Polyurethanes (TPU)

023: Ethylene-vinyl acetate (EVA)

024: Nylons (Polyamide PA)

025: Some ABS Resins

026: Special grades of Polyolefin (PP, PE, PET)

03: Important Factors

The most important factors influence Membrane Sealing High Frequency Curved Welding Machine: #1: electrical power #2: pressure applied #3: welding time #4: cooling time, Finding the optimal process parameters will depends on your specific equipment, the materials involve and the specific geometries including thickness and area to be welded, achieving optimal results is often an experimental process guided by experience, as a guiding rule, the thicker material and focus on short welding times you need, the stronger electrical power you need