Tent Canvas Tarpaulin Welding HF Welder for PVC PU Membrane Dielectric Sealing RF Welder of Awning Sunshades Seam Welding Sealer

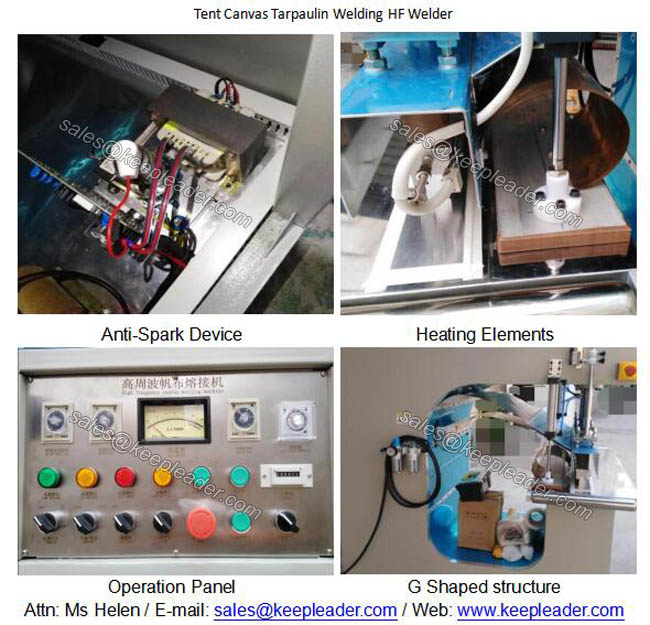

Tent Canvas Tarpaulin Welding HF Welder

01: Application

Tent Canvas Tarpaulin Welding HF Welder is especially designed for membrane structure seam sealing, HF welder is used for thermoplastic welding, the poly material has dielectric content, electric field is generated in the joining area, molecular friction cause the inside melting and apply pressure in dwell time in resulting in the stronger bonding force even that its original material, industrial PVC, PU or their coating cloth/textile/tents/tarpaulin is advanced tech in high frequency molecular friction melting, can build consumption product like pool-liners, oil-booms, water cisterns, tarpaulin, tents, tensile structure, advertising billboards, spark protection cloth, truck tent, canvas of agricultural, canopy, swimming pool cover, PVC digesters, Film cloth, gas storage bag, sunshades, flexible tanks, inflatable boats/booms/arches/castle, stretched ceiling structures, all of made of material of PVC/PU scale 20% are available

02: Parameter

| Name | Tent Canvas Tarpaulin Welding HF Welder | |

| Model | KLR-5KW-SN | KLR-8KW-SN |

| H.F Power | 5kw | 8kw |

| Input Power | 8KVA | 15KVA |

| Voltage | 3P, AC 220V/380V/415V 50/60HZ optional | |

| Rectifier | Silicon Diode | |

| Welding Time | 0.01~9.99S | |

| Frequency | 27.12MHz | 27.12MHz |

| Oscillation Tube | 7T85RB | 7T69RB |

| Max. Pressure | Pneumatic 350kgs | 500kgs |

| Upper Electrode | 50*50*600mm | 50*50*800mm |

| Lower Platen | 350*750mm | 450*1050 |

| Electrode Travelling | 150mm | 150mm |

| Throat Depth | 400mm+ made as requested | |

| Arc suppressor | 5557 High sensitive Anti-spark device | |

| Net Weight | 600kgs | 800kgs |

03: Character

Anti-spark device: when spark occur, the high sensitive spark protect electronic system cuts high frequency power immediately to protect mold, rectifier and material

Safety device: when the current exceeds its limits, the overload relay functions automatic protect oscillation tubes and rectifier, frequency deviation caused by misoperation is also prevented

Mechanical structure is robust and convenient operation for large scale tarpaulin welding

Easy tuning and special protection circuit: the electable output power ensured stable quality of the products for it could reduce the heating time when jointing is being carried out

Equipped with frequency stabilizer and high-frequency magnetic leakage suppressor, this

device eliminates the leakage of radio wave to interfere other electronic device

Single or dual lines in a circle welding is available

G/C/F frame welded structure with integrated HF generator

Custom requested size of work tables and welding platen acceptable

Heated upper platen with thermostat for helping HF sealing process

Universal usage for PVC, PET-G, A-PET, GAG, PU, PET, PLA films

Dual control system at two side for convenient access its operation

Pedal valve is also coupled with optional trigger and emergency stop

Customized work table dimension, electrode holder dimension, tooling

Laser guide projector at two sides used for quick material position guidance

Length, width and radian of welding area is changeable by various electrode

Close off HF welding function, the machine can be used as standard heat welder

Tent Canvas Tarpaulin Welding HF Welder G structure HF welder for canvas/tarpaulin with popular HF Power:5kw and 8kw, Throat Depth, Platen, Electrode Size made as requested

Tent Canvas Tarpaulin Welding HF Welder has basic consideration of reliable welding, convenient operation, compact structure, affordable cost with long time practical feedback from our oversea clients, keepleader also accept advanced configuration for exclusive combination for each expectation

Tent Canvas Tarpaulin Welding HF Welder is often weld membrane structure products made of PVC, PU, and their coated Fabric, also have function of heating melt bounding to assit on HF/RF welding no some HF/RF no-weldable material