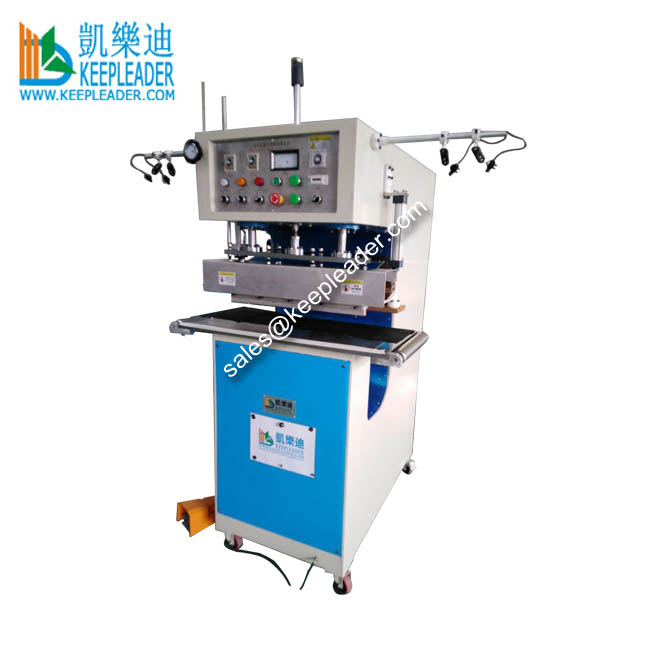

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine for Canvas_Membrane Overlap Bonding_PVC High Frequency Welding Machine

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine

01: Application

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine known as radio frequency (RF welding) or dielectric welding, bar welding, is the process of fusing thermoplastic membrane structure material together by applying radio frequency energy to the area to be jointed, the heating process in RF welding occurs from the inside out, so the seam sealing is just molecular scale bonding without damage around the welding area, the overlapped joining seam is robust, even can bear the bigger tearing and pulling force that the material itself, Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine has advantages in welding process of awnings, canopies, Geodesic domes, inflatable buildings, shelters, tents, oil booms, water tanks, water cistern, Banner, Billboard, strength ceiling, Tarpaulin, Canvas, soft window curtain, for HF/RF non-weldable textile made of PET, PP, the welding bar can equip in pulse heated bar to melt the heated melt tape laminated to complete the welding, with many years of practical improvement, our Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine can satisfy various bonding requirements with additional solution

02: Parameter

| Name | Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine | ||||

| Type | KLR-5KFW | KLR-8KWF | KLR-10KWF | KLR-12KFW | KLR-15KWF |

| HF Power | 5kw | 8kw | 10kw | 12kw | 15kw |

| Frequency | 27.12MHZ | 27.12MHZ | 27.12MHZ | 27.12MHZ | 27.12MHZ |

| Power Supply | 8KVA | 15KVA | 18KVA | 20KVA | 25KVA |

| Oscillation | 7T85RB | 7T69RB | E3069 | E3130 | 8T85RB |

| Driving Mode | Pneumatic | Pneumatic | Pneumatic | Pneumatic | Pneumatic |

| Pressure | 500KG | 500KG | 500KG | 800KG | 1000KG |

| Welding time | 0~10S | 0~10S | 0~10S | 0~10S | 0~10S |

| Up Electrode | 50*50*600 | 50*50*800 | 50*50*800 | 50*50*900 | 50*50*900 |

| Working Table | 350*700 | 450*1050 | 450*1050 | 450*1150 | 450*1150 |

| Rectifier | Silicon Diode | ||||

| Power source | AC 380V, 3P, 50/60HZ or made to order | ||||

| Electrode Gap | 150mm | 150mm | 150mm | 150mm | 150mm |

| Active horn | 150mm | 150mm | 150mm | 150mm | 150mm |

03: Advantages

Creates airtight and waterproof seams unlike when you sew and are poking holes into the fabric weld the same area more than once with on damage to the fabric

Specialized dies are made available for intricate welds seams that are stronger that the material itself for a diverse manufacturing job

Tarpaulin Seam RF Welder is highly affordable, especially if you choose our free-standing model

The process of Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine is designed to maximize sealing while minimizing the likelihood of damaging other parts of your material

Welding PVC with Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine will not generate any toxic smoke that could damage the environment

The end of result of sealing PVC with Tarpaulin Seam RF Welder is a smooth, streamlined product that you will be proud to show your customer

04: Character

Universal usage from PVC, PU, TPU, reinforced technical textiles

HF power can be 5kw~25kw for different welding bar size required

PE, PP polyester, Nylon weld ability with optional impulse electrode

Length. Width and radian of joining seam can be matched by exchangeable bar

Firmly welding, be well meet with thick or think dimension of welding material

Simple to set up and easy to operate in setting RF power, timer, pressure and balance

Sealing efficiency from 1kw up to 40 square centimeters for standard PVC material

Tarpaulin Seam RF Welder has wide application with interchangeable electrode bars

Big depth of material trough/throat behind the electrode which makes the welder suitable for large scale manufacturing that require extensive material handling

Infrared laser scanning system to form a guiding width for overlapping position

European model high frequency vibration cavity is more reliable and stable in output

International industrial wave bands 27.12MHz which is in line with international standard

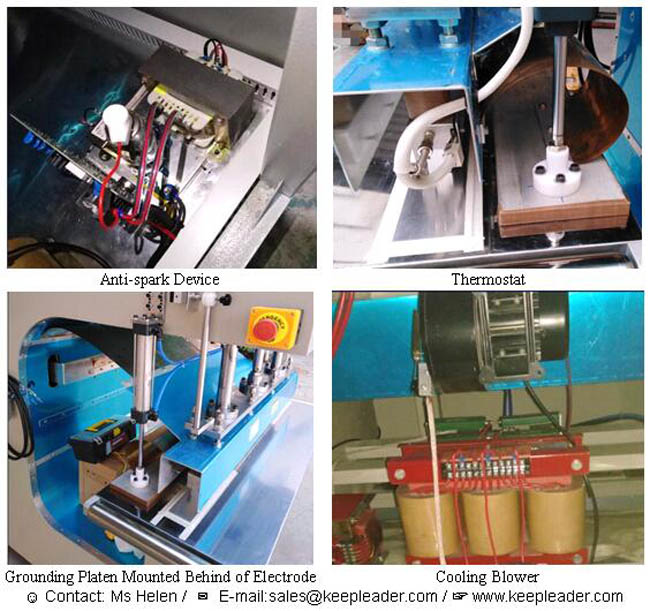

Adopting high sensitive anti-sparkle decide NL-5557/arc suppressor to protect the mold and material in overcurrent/overload condition

Tarpaulin Seam RF Welder has smooth glide wheels for easy movement in-around welded fabric, or relocation to desired place in manufacturing hall

05: warning

Key considerations in RF tooling include ensuring that uniform thickness is maintained, as well as the removal of any sharp edges or corners. It is also imperative to determine the appropriate level of RF energy that is fed into the seal area. Using RF sealing equipment that contains a generator with a high-quality arc suppressor will help regulate the voltage output by stopping the output before damage to the plastic film or die can occur. This will also ensure the temperature does not drop to a level that is insufficient for sealing to take place.

A handy way to secure the material in the required position on the welding table is using magnets, which are positioned on the material when it is put in the right position on the welding table, a magnetic band is placed onto the welding table and it secured with stretched on both side of the table, the magnets hold the material in place until welding is complete, magnets are available in different strength to suit different material thicknesses, and there are two magnets per meter table, the width of magnets band depends on the machine model, sand bags or similar can also be used to secure the material while welding

Keep the highest scale of cleanness on the electrode bar and surface of bonding area, the debris or any foreign particles entrapped into the welding area or adhered on the bottom of electrode/welding bar can create HF deviation, instant Higher RF scale always comes with the process of arc suppressor, if in this case, please immediately to remove the dirty prior to restore the operation after emergency stop

06: service

On-site assessments by dedicated service engineers

Technical support via phone or email with a live representative

Provide new components to replace the defected or broken parts

After service for trouble shoot, maintenance and refurbishing solution

Expertise working with all major brand radio frequency welding machine

Diagnosing issues and have the training to service all types of RF Equipment

Fast response to correct any problems negatively impacting your productivity

Complete product re-build capabilities and cost-effective replacement options

Welding knowledge, service and support for membrane structure bonding solution

Customized tooling for FR welder to comply with various seam sealing application

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine and service of its operation and maintenance

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine joins materials together by supplying high frequency (HF/RF) in the form of an electromagnetic field and pressure to the surfaces of the material to be joined, energy is produced by a generator, supplied through an electrode tool, electrical energy causes molecules within the material to flip and friction in a new realignment orientation, the molecular friction in disunity generating heat that causes the material to soften and fuse together, no outside heat is required which produce the polymer bonding without damage around but stronger than the material itself

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine

Making the decision to purchase Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine for your manufacturing company is often a wise decision, but it is important that you find the right supplier for your RF bar welders to get the best results, we can say with confidence that you can trust keepleader as your supplier, with many years under our belt supplying high quality RF welding machines to business, our reputation is one you can count on, we are one of Leaders in best of best quality, reliable service, cost-saving solution, trouble-free cooperation

Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine is used for seam bonding in #1: small and large format technical textiles PVC or PU coated #2: Tensile structures, tents, shade systems, truck covers and side contains #3: swimming pool liners and covers, flood dams and water tanks #4: airport hangars, portable storage structures #5:containment pools, oil booms, ground liners #6: advertising signs and large format billboards

KEEPLEADER provides industry-leading Tarpaulin Seam RF Welder Tent Sealing HF Welding Machine that are durable, reliable, and effective, contact us directly today so we can learn more about your specific equipment needs and provide a lasting solution

☺ Attn: MsHelen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com