Tarpaulin Canvas Seam Sealing High Frequency Welding Machine of PVC Tent_Truck Cover_Awning_Fabric Radio Bonding H/RF Bar Welder

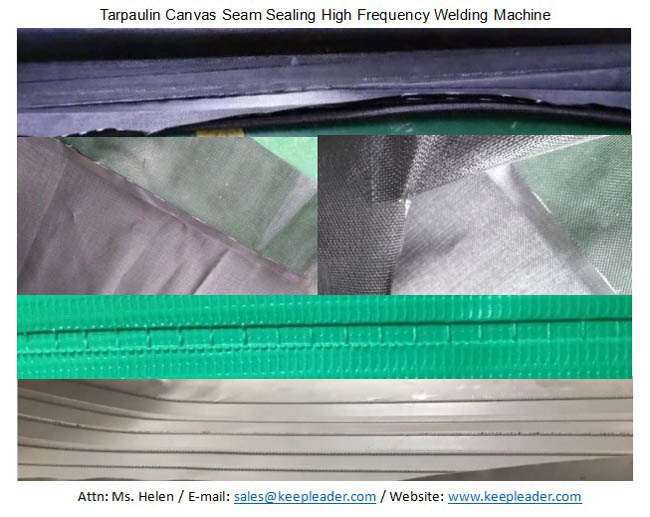

Tarpaulin Canvas Seam Sealing High Frequency Welding Machine

01: Applicable Introduction

Tarpaulin Canvas Seam Sealing High Frequency Welding Machine plays a seam sealing role for the production of tents, large awning, canopy, large advertising banner, pool-liners, oil-booms,water cistern, swimming pool covers, billboard, large signs, military tent, clear span building, biodegradable digested container, all of High frequency weldable material in membrane structure are available, such as PVC,EVA, PE,PU,TPU and so on, using HF energy in the form of an electromagnetic field to provide uniform heating and pressure to bond thermoplastic, no external heating is required for the joining of PVC and PU materials, Tarpaulin Canvas Seam Sealing High Frequency Welding Machine also named high frequency dielectric bar seam sealing, which is likely heating principles of microwave oven, the temperature is raised from inside in molecular scale,its bonding force is stronger that the matrix itself, which has prominent solution in polymer seam jointing, the output power of our Tarpaulin Canvas Seam Sealing High Frequency Welding Machine up to 35kw with deep material trough behind the electrode plate provides advanced technological features for optimizing productivity, stabilized and strong regulated HF vibrators can provide efficient power for linear welding up to 1500mm of length in a circle and 50mm of width, it also equipped with a laser scanning positioning system, convenient for the operator to position

02: Tech Data

| Name | Tarpaulin Canvas Seam Sealing High Frequency Welding Machine | |||

| Model | KLR-5KW-SN | KLR-8KW-SN | KLR-12KW-SN | KLR-15KW-SN |

| HF Power | 5000w | 8000w | 12000w | 15000w |

| Input Power | 8.5KVA | 15KVA | 18KVA | 25KVA |

| Max Pressure | 500kgs | 500kgs | 800kgs | 1000kgs |

| HF Frequency | 27.12MHz | 13.56MHz | ||

| Voltage | 220v,60hz or 380v,50hz three phase | |||

| Rectifier | Silicon Diode | |||

| Arc Suppressor | NL-5557 High sensitive anti-spark Tube | |||

| Oscillation Tube | 7T85RB | 7T69RB | E3130 | 8T85RB |

| Max Pressure | 350KGS | 500KGS | 800KGS | 1000KGS |

| Operation Mode | Pneumatic Operated | |||

| Electrode Gap | 150mm | |||

| Active Horn | 150mm | |||

| Welding Time | 0.01~9.99s adjustable | |||

| Driven Mode | Pneumatic activation | |||

| Upper Electrode | 50*50*50mm | 50*50*600mm | 50*50*800mm | 50*50*900mm |

| Work Table | 350*700mm | 450*800mm | 450*1050mm | 400*1150mm |

| Net Weight | 700kgs | 780kgs | 900kgs | 1100kgs |

03: Salient Advantages

Versatile applicable solution in seam joining of membrane structure

Length, width and radian of joining area can be tailored by select-able welding bar

Big throat of material-trough to storage positioning material for large size weldable object

Infrared laser projector to guide the positioning in alignment of overlapping joints

European standardized square oscillation cavity generate reliable and stable in HF output

International industrial wave bands 27.12MHz and 13.56MHz with lowest fluctuation

Arc-suppressor adopts high sensitive NL-5557 anti-spark tube to protect the welding bar

Precision controlled actuation in pressing to suit different thickness welding material

5KW to 25kw HF power output in optional model to vary with length of welding bar

Power Circuit designed with auto tuning HF to keep the power output at utmost scale

Digital setting parameters of welding time, HF power, dwell time, pressure and Down time

Tarpaulin Canvas Seam Sealing High Frequency Welding Machine applies for seam sealing process for membrane structure via internal excited heating to achieve bonding in molecular scale, its principle similar to microwave, however, instead of heating water or food, a HF welder heats a metal bar and fabric of your tarpaulin through exciting the molecules within the radio waves, this excitation gives those molecules a negative electrical charge thousands of time per second,creating intense heat friction that allow the bar to apply pressure and create an incredibly tight seal, this bonds you tarp’s fabric as tightly, or more tightly, than if you has sewn it down, just much quicker and efficient

Our Tarpaulin Canvas Seam Sealing High Frequency Welding Machine is durable, reliable and effective, constructs with welded steel frame and renown brand electronic components,self-tuning high frequency energy to exert consistent sealing, builds infrared laser projector for positioning material and deep material trough to go through the large material for ready working, bespoke functionality and dimension are acceptable

Tarpaulin Canvas Seam Sealing High Frequency Welding Machine construct deep material trough behind the electrode in high frequency dielectric bar welder, which applies for seam sealing in large format structural membranes, such as pool-liners, oil-booms, water cisterns, tarpaulin, tents, tensile structures, advertising billboards, spark protection cloth, tent of truck, canvas of agricultural, canopy, swimming pool covers and other PVC,PU,TPU technical textiles, large PVC canvas, biodegradable digester, awning, sunshades cover and etc

Tarpaulin Canvas Seam Sealing High Frequency Welding Machine sees our year-by-year’s progress and growth for over decades, keepleader, we provide the highest quality HF bar welder, particularly for seam sealing of membrane structure, we have a range of bespoke machines to meet both your budge and your goals for your business, we believe our combination of experience, flexible solution and commitment to customer satisfaction is the key to our success and is why you want to work with us now and in the future for your HF welding applications, we are always ready for your initiation to start our one-stop service

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com