Treadmill Belt Joint Welding High Frequency Welding Machine for Running_Conveyor PVC PU HF welding of Treadmill Belt RF Welder

Treadmill Belt Joint Welding High Frequency Welding Machine

01: Application

Treadmill Belt Joint Welding High Frequency Welding Machine is specially designed HF welder for profiles welding in treadmill belt, treadmill belt splice joint sealing, treadmill belt splicing finger sealing, conveyor belt, industrial belt, transmission belt, T-cleats, L-Cleats, belt skirt, v-guide, belt baffles and other cleats, made of TPE, PU, PVC and other thermoplastic

02: Advantages

Treadmill Belt Joint Welding High frequency (HF) welding process, also known is Treadmill Belt radio frequency (RF) and Treadmill Belt dielectric welding, consist of amalgamation of Treadmill Belt by supplying HF energy in the form of an electromagnetic field 27.12Mhz and 13.56MHz which is normally applied between two metal electrodes, plates or moulds, Treadmill Belt HF welding is accompanied with certain pressure on the Treadmill Belt surfaces to be joined, for this purpose, HF welding machine are constructed

Treadmill Belt HF welding replies on certain properties of the Treadmill Belt being welded to cause the generation of heat in rapidly alternating electric field, so called dielectric heating of the Treadmill Belt to be welded, this means that only certain Treadmill Belt to be welded using this technique, the dynamic electric field causes the molecules in polar thermoplastics to oscillate, depending on their geometry and dipole moment, these molecules may translate some of this oscillatory motion into thermal energy and cause heating of the Treadmill Belt, a measure of this interaction is the loss factor, which is temperature and frequency dependent

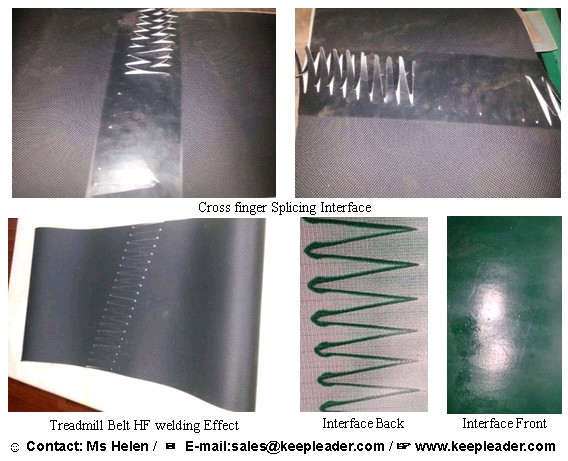

Treadmill Belt Joint Welding High Frequency Welding machine utilizes high frequency electromagnetic field to make internal molecular of treadmill belt rearrange, the effect of belt welding is beautify and robust, and, the tear stretching of welding is close or stronger to the strength of raw material

03: Parameter

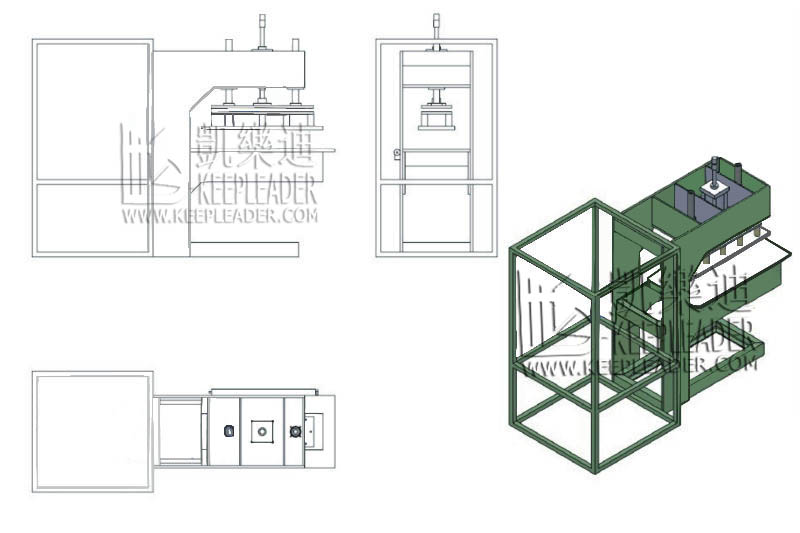

| Treadmill Belt Joint Welding High Frequency Welding Machine | |||

| Model | KLR-8KWC | KLR-15KWC | KLR-25KWC |

| HF Power | 8000W | 15000W | 25000W |

| Power supply | 380v,3 phase (optional:220v,60hz,3 phase) | ||

| HF Frequency | 27.12MHz | 13.56MHz | |

| Electronic power | 20KVA | 25KVA | 40KVA |

| Rectifier | Silicon Diode | ||

| Electronic Tube | E3069RB | BT85RB | 8T25RB |

| Max pressure | 400kg | 600kg | 1000kgs |

| Electrode gap | 200mm | ||

| Active Horn | 200mm | ||

| Upper Electrode | 400*150mm | 700*250mm | 1000*300mm |

| Down electrode | 500*150mm | 800*250mm | 1100*300mm |

| Temperature scale | adjustable :30~200 | ||

| Welding Time | Adjustable: 0~10s | ||

| Productivity | <=5000times/8h | ||

| Dimension (mm) | 1920*1200*2060 | 2650*2550*2240 | 2850*2550*2440 |

04: Character

Material groove is deep and wide, is convenient to weld large size

Built-in High Sensitive spark protect device to avoid damaging the electrode

Welding length can be extended to 1300mm or longer for on cycle

Stable HF: international industrial band is 27.12MHZ or 13.56MHZ

Strong output: Low-consumption coaxial oscillator, coherent tuner, strong output force to shorten welding time and increase production

Quick change tooling: reduce downtime during tooling changeover

Welding size is changeable by custom electrode and fixture in variety

Precision HF tuner in controlled by different welding shape, material & its thickness, and size

High sensitive anti-spark device to protect the welding electrode and products

Reinforced frame: stable and durable

Over-current protection power circuit for safe operation

Treadmill Belt Joint Welding High Frequency Welding Machine can not only weld treadmill but also can weld conveyor belt, transmission belt and other industrial belt

Advantage of high frequency (HF) welding machine

The great advantage of HF welding is the speed of welding: the material is heated form the inside and fuse quickly within few seconds, in comparison with HF or RF, in all other kinds of welding methods (with filaments, hot air or infrared radiation) the heat has to be added from the outside, it means the heat must first penetrate the material in order to make it plastic enough to form a weld, the main risk of this kind of treatment is burning the top layer of welded material

A high frequency voltage trigger the heating within the material, no extrinsic warming applied, generated heat causes melting of materials and their integration, after cooling the welded surface under maintained pressure, the material is fused and a weld has been created, the weld joint can be at least as strong as the surrounding material or even stronger

What factors contribute to a good weld?

Typical plastic High Frequency (HF) welding HF welds consist of a high frequency generator (which creates the radio frequency current), a pneumatic press, an electrode that transfers the radio frequency current to the material that is being welded and a welding bench that holds the material in place, many factors affect the strength and seal quality in HF/RF welding, tooling layout, welding thickness, material thickness, and machine control are some of the most important factors in creating a good seal, the appeal of HF/RF welding is in the completeness of the weld, using this method can create very robust hermetic seals, many welds are subject to pull tests, leak tests, and optical tests to determine that the correct conditions have been achieved

Final products done with HF welding

Common products manufactured with HF welding method are tarpaulins, tents, advertising outdoor banners, stretch ceiling. Waterbeds, inflatable products, Medical bags, tensile structures, conveyor belts, rain clothing, plastic blister packages, and other thermoplastic membranes

What materials can be welded by high frequency (HF/RF welder)?

The material most common in high frequency welding (HF/RF welds) in PVC (something called simply vinyl) and PU (polyurethane), the material can be thick or thin, reinforced or coated, it can also be plain, colored or structure/patterned

PVC and PU (polyurethanes are the most common thermoplastic that are available in HF welds, it is also possible to perform HF welding on other types of material including nylon, PA, ABS, modified TOP, PETG, but particular attention should be pay on working parameters, HF welding is mot suitable for PTFE, polycarbonate, polystyrene, polyethylene or polypropylene. However, a special type of mixed fabrics have been produced recently, which have the capability to be HF welds high frequency welding