PVC_PU Profile Cleat_Sidewall Welding Machine for Conveyor Belt High Frequency Welding of Conveyor Belt High Frequency Welding

PVC_PU Profile Cleat _Sidewall Welding Machine for Conveyor Belt

01: Application

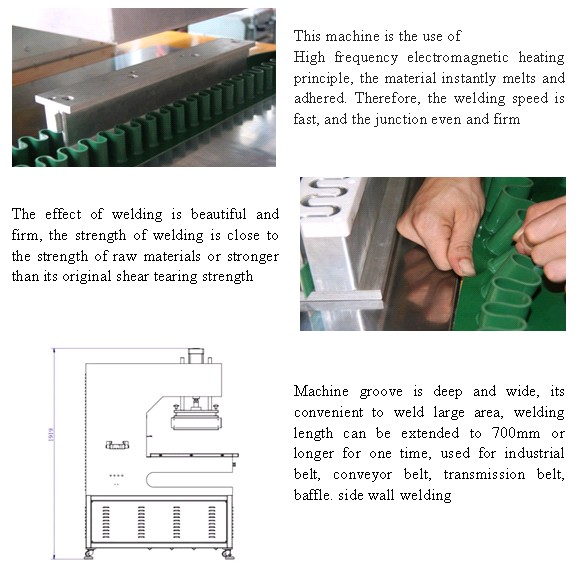

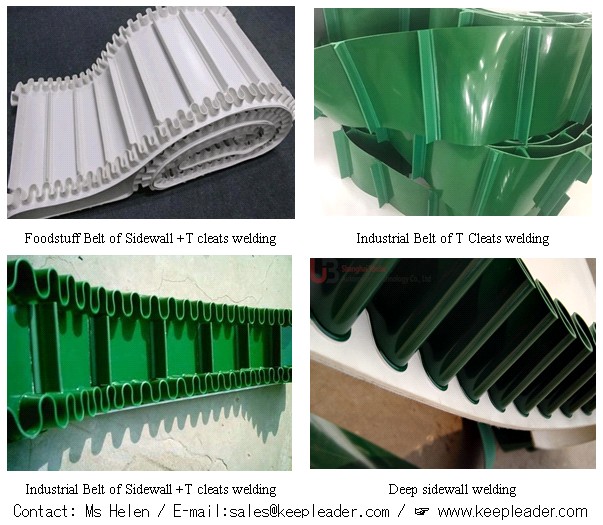

PVC_PU Profile Cleat _Sidewall Welding Machine for Conveyor Belt is designed specially for production of industrial belt, transmission belt, PVC/TPU conveyor belt of PVC/PU sidewall, PVC_PU profile, PVC_PU cleat, PVC/PU steps, PVC_PU treadmill, PVC and PU guides, T-Cleat, treadmill belt, this conveyor belt welding utilizes high frequency (H.F/R.F welding) electromagnetic field to make its internal molecular rearrange without outside heated, the effect of welding is more firm and beautiful, the bonding strength can reach, even over strength of raw material

02: Parameter

| Name | PVC_PU Profile Cleat _Sidewall Welding Machine for Conveyor Belt | |||

| Model | KLR-8KWC | KLR-15KWC | KLR-25KWC | KLR-35KWC |

| Power | 8kw | 15kw | 25kw | 35kw |

| Voltage | 380v~420v, 50hz or 210~240v,60hz* three phase | |||

| Frequency | 27.12MHz | 13.56MHz | ||

| Input Power | 15KVA | 25KVA | 35KVA | 50KVA |

| Rectifier | Silicon diode | |||

| Throat depth | 1150mm | |||

| Oscillation tube | 7T69RB | 8T85RB | 8T25RA | 8T87RB |

| Max pressure | 800kg | 1000kg | 1500kg | 1500kg |

| Operation mode | Pneumatic | |||

| Electrode distance | 150mm | |||

| Moving distance | 150mm | |||

| Upper electrode | 150*500mm | 150*600mm | 150*700mm | 150*800mm |

| Lower electrode | 250*650mm | 250*750mm | 250*850mm | 250*950mm |

| Welding time | 0.01~9.99s | |||

| Net weight | 1200kgs | 1500kgs | 1800kgs | 2000kgs |

| Dimension | 1.6*1.48*1.74 | 1.7*1.48*1.74 | 1.98*1.48*2.35 | 2.05*1.48*2.5 |

03: Character

Firmly welding for PVC, PU, PET profiles belt welding

Deep and wide groove design is convenient for large area in continuous welding

Auto detecting cooling performance can well protect the oscillation tube

Adopting high sensitive anti-sparkle device to avoid damaging the mold

All of apparatus are in compliance with international standard for convenient replacement

The longest welding extended to 800-1000mm one time

Ground-press platen is behind welding tooling good for operation and to protect the workers from hurt hands

With hanging head for welding without barrier of the machine, it is convenient for operation

With high frequency stabilizer and shielding device to keep the H.F interference at lowest level

The most important factors influence PVC_PU Profile Cleat_Sidewall Welding Machine for Conveyor Belt: #1: electrical power #2: pressure applied #3: welding time #4: cooling time, Finding the optimal process parameters will depends on your specific equipment, the PVC,PU involve and the specific geometries including thickness, size and area to be welded, achieving optimal results is often an experimental process guided by experience, as a guiding rule, the thicker material and focus on short welding times you need, the stronger electrical power you need

PVC_PU Profile Cleat_Sidewall Welding Machine for Conveyor Belt can have #1:T-Cleats tooling #2: sidewall tooling #3: Curve Guides tooling

PVC_PU Profile Cleat_Sidewall Welding Machine for Conveyor Belt has quick mounted tooling or changeover tooling for welding in various shape and size

PVC_PU Profile Cleat_Sidewall Welding Machine for Conveyor Belt utilizes H.F electromagnetic field applied molecular friction in rearrangment without outside heating, so the melting and bounding is achieved from inside