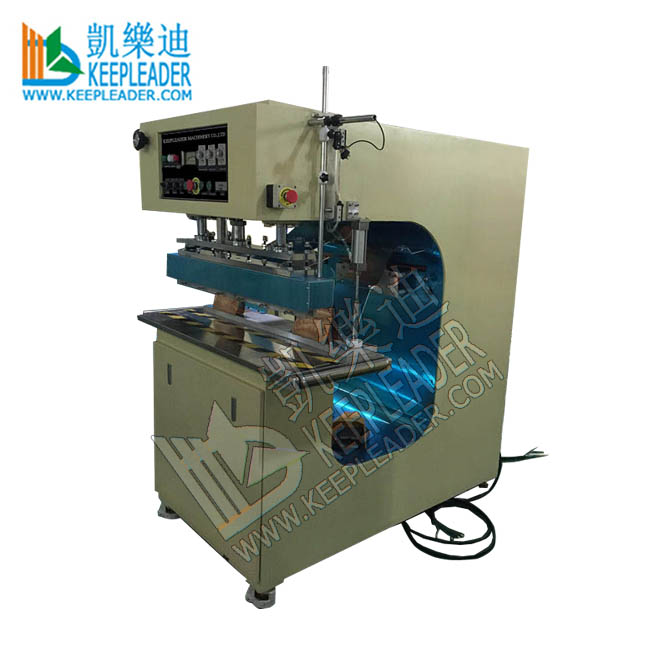

PVC Vinyl High Frequency Welding Machine for PVC Vinyl Billboard_Liners Pool HF Welder of High Frequency Tent_Tarpaulin Welding

PVC Vinyl High Frequency Welding Machine

01:Application

PVC Vinyl High Frequency Welding Machine replies on certain properties of the material being welded to cause the generation of heat in a rapidly alternating electric field,so call dielectric heating of the material to be welded, this means that only certain materials can be welded using HF welding, the dynamic electric field causes the molecules in polar thermoplastic to oscillate, depending on their geometry and dipole moment, these molecules may translate some of this oscillatory motion into thermal energy and cause heating of the material, a measure of this, interaction is the loss factor, which is temperature and frequency dependent, PVC Vinyl High Frequency Welding Machine is professional equipped with material tough of go-through large size seam sealing, inflexible products made of industrial canvas, PVC tent, PVC tarpaulin, PVC stretch ceiling, raincoat, inflatable toys, waterbed, large-scale advertising banner, awning, canopy, PVC membrane signs, billboard, truck cover, sun shading PVC Fabric, painting canvas, film curtain and relative thermoplastic sheets/cloth

02:Parameter

| Name | PVC Vinyl High Frequency Welding Machine | ||

| Model | KLR-8KWF | KLR-12KWF | KLR-15KWF |

| HF Power | 8kw | 12kw | 15kw |

| Voltage | 380v,50hz or 220v,60hz three phase | ||

| HF Frequency | 27.12MHz | ||

| Rectifier | Silicon Diode | ||

| Electrode gap | 120mm | ||

| Electrode travel | 100mm | ||

| Input Power | 15KVA | 20KVA | 25KVA |

| Oscillation tube | 7T69RB | E3130 | 8T85RB |

| Melting Pressure | 400kgs | 600kgs | 800kgs |

| Throat Depth | 100cm | 100cm | 120cm |

| Upper Electrode | 1000*50*50mm | 1000*50*50mm | 1200*50*50mm |

| Bench Length | 1200mm | 1200mm | 1400mm |

| Net Weight | 600kgs | 700kgs | 800kgs |

03:Character

G Shaped frame has deep throat depth/material trough can process infinite long material

Anti-spark electric system: when the spark occurring, the high sensitive spark electric device will cut the HF power immediately to protect the electrode and material

Easy tuning and special protection circuit: the selectable output power can ensure the stable quality of the bonding while the welding process, its could largely reduce the heating time

High frequency radiation suppression: this HF welding machine has a good shielding device, all the parameters has passed the inspection of the state department

Laser lighting the overlap positioning line to guide the seam

Three sets of triggering and stopping channel for convenient operation

European type of oscillation cavity also equipped with cooling blower to guarantee the safe and reliable power output and best performance

Can select the HF limit with visible meter in tuning HF output in melting process

Solenoid valve controls the stroke distance/electrode travelling distance

Pressure, melting time, dwell time all is visible selected to align a combined parameter for welding material in versatility

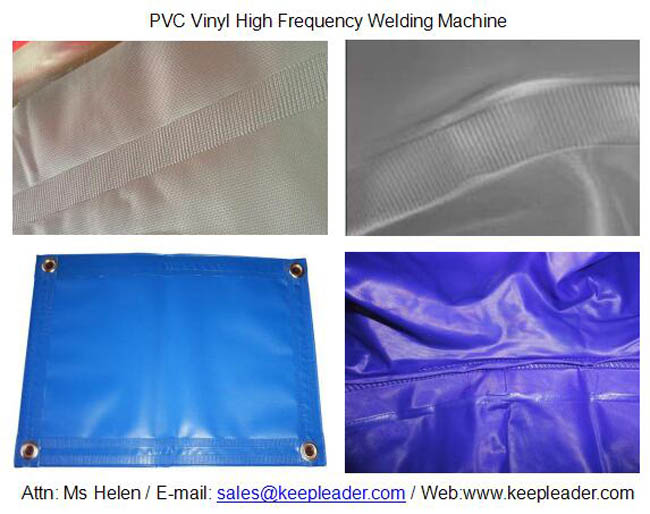

04:highlighting of HF Welding for PVC Vinyl

PVC Vinyl High Frequency Welding Machine has great advantage, not only has tear-resist bonding force but also has quick speed melting and solidification, the PVC tarpaulin is heated from the inside and fuses quickly with few seconds, compared to high frequency welding, a lot of other methods (hot air, infrared radiation, laser) the energy/heat is supplied from outside, this means that the heat must first penetrate the material in order to heat the contact-surfaces, thus risking to burn the top layer of the welded surface

PVC Vinyl High Frequency Welding Machine can select the HF power basing on your welding material, size and thickness in 5kw~25kw

PVC Vinyl High Frequency Welding Machine is freestanding HF welder, which also can be used a travelling welder

PVC Vinyl High Frequency Welding Machine is capable for PVC, TPU, or its coated Fabric dielectric sealing to make various flexible products