PVC Tent High Frequency Welding Machine for Tarpaulin_Canvas_Truck Cover_Membrane Structure Military Tents Sealing HF/RF Welders

PVC Tent High Frequency Welding Machine

| Mainly application of PVC Tent High Frequency Welding Machine | |

| PVC Tent High Frequency Welding Machine Applied for tarpaulin, sun shading canvas, painting canvas, film curtain, canopy,awing,truck cover, car tent,stretch ceiling, sunshades and other around of this kind of membrane structure material welding or sealing | |

| Character of PVC Tent High Frequency Welding Machine | |

| High Q value oscillation tube

the welding length is optional, maximum length:2000*25mm for 25kw The machine is G shape, have longer throat to hold the material High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output Laser position device for precision counterpoint Have boosting roller at two side for easy feeding materail Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safty purpose Anodized mould and tooling for longer life-span Top amounted cylinder for vertical pressing, which is more uniform pressure Foot pedal control and button control is optional Over current protection circuit to avoid burning the oscillation tube Power ranges 4kw up to 25kw for various welding length |

|

| Technique specifications of PVC Tent High Frequency Welding Machine | |

| Model | KLR-5KW-SN |

| Power | 5000W |

| Power supply | 220V/380V 50/60HZ |

| Frequency | 27.12MHZ |

| Input power | 8KVA |

| Rectifier | SILICON DIODE |

| Oscillation tube | 7T85RB |

| Max pressure | 350kg |

| Gap of electrodes | 100MM |

| Moving distance of active horn | 100MM |

| Size of upper electrode | 600*30MM |

| Size of down electrode | 1000*300MM |

| Welding time | 0~10S Adjustable |

| Net weight | 500KG |

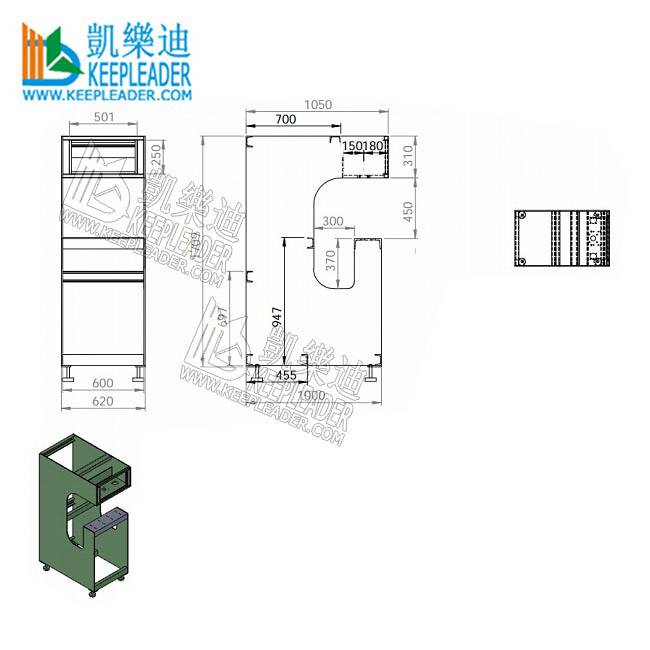

| Overall dimension | Customized |

Standard equipment:

| Name | Origin | Brand |

| Air driven components | Taiwan | Airtac |

| AC contactor | Korean | LG |

| Relay | Japan | Omron |

| Electron Tube | Japan | Toshiba |

| Time controller | Taiwan | CKC |

* Note: The parameter herein stated is manually measured, the actual machine has possibility in little difference, if have crucial demand in its application, please double check with our sales, only paper confirmed will be regarded as contracted obligation

Please tell us following information:

❶ The material and definite size of the product;

❷ The maximum welding length in maximum

❸ The features you preferred on this machine

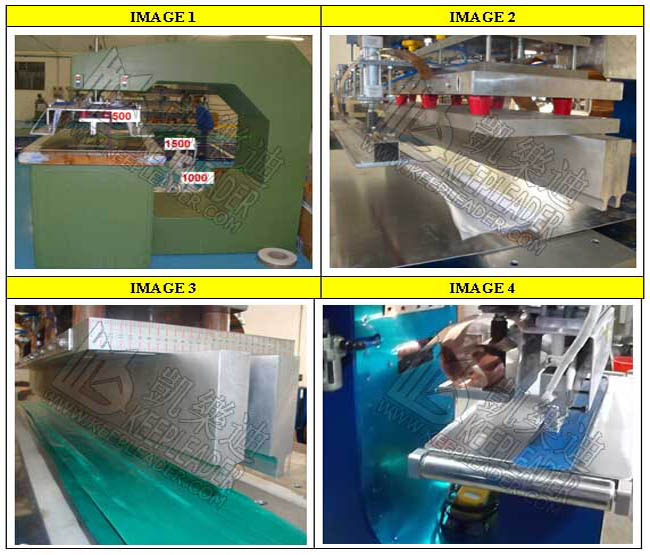

PVC Tent High Frequency Welding Machine has optional ranges of power output: 5kw~25kw depending on welding material and size, this free-standing model of 5kw has maximum length of electroded bar in a circle welding:600mm

PVC Tent High Frequency Welding Machine has sailent features of #1: customized dimensional material-trough #2: Optional in single and dobule bonding line #3: adjustable welding width if two lines required #4: sliding assited rolls at two sides of working plate

PVC Tent High Frequency Welding Machine contructs deep material-trough used for going through accumulated material in welding large-scale tent, its dimension can made to order

PVC Tent High Frequency Welding Machine is available for seam sealing of PVC 20% more Fabric tent in fabricating Canvas, tarpaulin, membrane structure, stretched ceiling, truck cover, army, billboards, signs, military tents

PVC Tent High Frequency Welding Machine is affordable, reliable, compacted, free-standing HF/RF weldler of building small scale tarpaulin tent in verstatile solutions, thanks to our technical teams, they continue to learn from practical maufacturing, listen to conerns from our clients around the world, hope our experimental staff can work with your esteemed company into a promising cooperation

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com