PVC Inner Page Making High Frequency Welding Machine of Vinyl Clear ID Card_Tag Pouches Holders Auto HF/RF Sealing

PVC Inner Page Making High Frequency Welding Machine

01:Application

PVC Inner Page Making High Frequency Welding Machine takes dielectric sealing in making PVC inner page,under the effect of the high frequency electric field, the positive and negative charges of the substance to be heated displace to form electric pole polaron,the polaron polarize repeatedly to cause the molecules to produce the intense friction to arise heat ou, the electric field energy absorbed by the substance charges into heat energy to realize the purpose of heating,because of cutting rim is built in the sealing mold, this high frequency welding machine can achieve the sealing and edge trimming simultaneously,moreover, the machine has automatic transmission system that mount the material in roll to execute auto feeding, the pitch-length is adjustable for versatile sizes sealing in multiple layers laminated films, PVC Inner Page Making High Frequency Welding Machine has sealing and cutting mold that arrange several pouches of specified size and shaped in one plate that is also reliable in medical bag making, such as urine bags, stoma bags,PVC flat bag, medical transfusion bag,blood bag,douche bag,catheterization bag and any other disposable bags

02: Parameter

| Keyword | PVC Inner Page Making High Frequency Welding Machine | |

| Model | KLR-5KW-CS | KLR-8KW-CS |

| HF Power Output | 5000w | 8000w |

| Oscillation Frequency | 27.12Mhz | 27.12Mhz |

| Rectifier | Silicon Diode | Silicon Diode |

| Max Pressure | 500kgs | 600kgs |

| Power Voltage | 380v/220v | 380v/220v |

| Max Input(KVA) | 6KVA | 15KVA |

| Oscillation Tube | T785RB | 7t69RB |

| Operation Mode | Pneumatic | Pneumatic |

| Electrode Distance | 150mm | 150mm |

| Stamp Stroke | 150mm | 150mm |

| PVC Thickness | 0.03~0.27Mhz | 0.03~0.27Mhz |

| Size of Upper Electrode | 400*500mm | 500*700mm |

| Size of Down Electrode | 400*500mm | 500*700mm |

| Temperature Range | 30~200 Celsius | 30~200 Celsius |

| Welding Time | 0~10 Adjustable | 0~10 Adjustable |

| Productivity | 360times/hour | 360times/hour |

| Machine Size | 6200*1300*1600mm | 6280*1380*1688mm |

| Packing Size | 6400*1500*1800mm | 6480*1580*1883mm |

| Weight | 1800kgs | 1900kgs |

03: Salient Character

3~5pcs unwinding roll auto-feeding in multiple-layers transmission

Tension control of servo motor driven to precise control the pitch length

Robust constructed frame of HF welding head,coupled with one set of sealing mold

Programmable logic control with touch screen built in operation panel

Operation soft adopts both English and Chinese Language in Menu version

Automatic stop when photocell can not track the material feeding to protect mold

Automatic counting the finished quantities and track the printed material

Tension control of material feeding in roll, transmission speed both are adjustable

Adopting abrasion resistance belt of transformation to avoid damaging the mold

Waste material collecting device is available as extra ancillary unit

Electric power control adopts advanced circuit results in high efficiency

Strong HF Power Output, but less electric wave leakage

Built-in sensitive arc suppressor device afford effective protection in case of over-current

Upper electrode plate is built in heating element of tabular type for thermal assistance

Equipped with high precision positioning system that can make the mold counterpoint accurate and greatly improve processing efficiency

Hanging poles can attain in integrated punching device of separated control

Rigid material can go through the auto flattening device of standing-along

Triple automatic protection system can effectively perform safe-guard

Molecular construction of each productive units integrate into production line

PVC Inner Page Making High Frequency Welding Machine adopts productive units of each specified functional processes that includes rigid material leveling device, material roll mounting rack,auto transmission, tension control system, auto pitch feeding, punching device, high frequency welding and cutting machinery, waste material auto collecting system, tear-off finished bags,these modular functionalities of built in separated processing units combine an automatic production line in PVC,PET,PP Bag making at versatile sizes and designs,PVC Inner Page Making High Frequency Welding Machine keeps its prominent performing because of many salient advantages that embody good-looking appearance, rational design,novel structure, strong practicality,reliable performance, efficient production, high automation level,perfect sealing,convenient maintenance, guaranteed longevity and intelligent operation

PVC Inner Page Making High Frequency Welding Machine attains its reputation in gratifying productive demands that cover over ten-years accumulation that are still growing to the level of each process stands at the top apex, molecular construction combines an efficient and effective production line in various PVC Bag making, its elemental criteria embodies advantages that consist of 1st: adopting automatic feeding device and collecting device;2nd:adopts sensitive sparks suppressor which protects mold and materials;3rd:automatic operation to reduce the cost of production and make the PVC bag in consistent effect;4th:air feeding device,precision distance,reduce the loss of material,and make sure that the strength is suitable to avoid material cracked;5th:automatic collecting device assists to save labor and increase the production output;6th:intelligent operation system, written programmable logic control with touch screen marries with servo-motor control feeding system, and photoelectric sensor,detector and tracker achieve auto transmitting, analyzing,setting,storing and diagnosing working data;7th:equipped with high precision positioning system that can make the mold counterpoint accurate and greatly improve processing efficiency

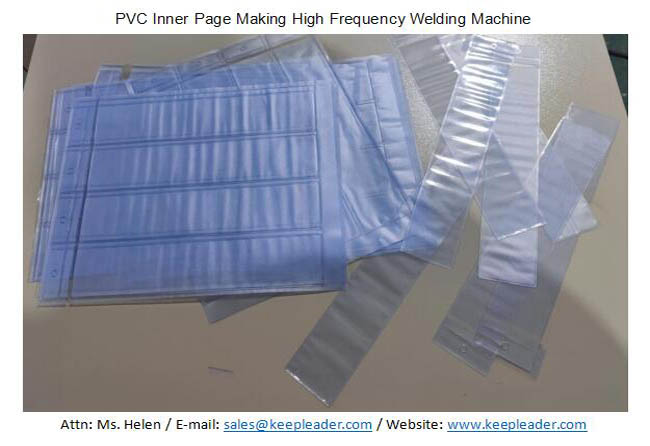

PVC Inner Page Making High Frequency Welding Machine is suitable for making PVC packaging bag, PVC inner page of album and name card, PVC business card, packaging Bag,CD bag, book cover, medical bag, such as catheterization bag,douche bag,urine bag, stoma bag and other disposable bags, this high frequency welding machine can mount PVC material in roll that is auto transmitted in multiple layers attaining laminated sealing and simultaneous achieving tear-off cutting in a cycle process. That also support changeable molds to gratify versatile sizes and shapes of PVC bags

Keepleader, we are professional manufacturer of bespoke machines in process polymer materials of cutting, sealing, forming, embossing,stamping and other peripherals, plastic products are widely used in industry packaging, electronics, house-hold appliance, aerospace, aviation, medical consumable products, stationary and etc, high frequency welding machine is made specially for production serving various industries: automotive,medical, rehabilitation, packaging, recreating, textile and clothing, reflective garments and so on,PVC Inner Page Making High Frequency Welding Machine is our specified solution in making PVC,PET,PP bags with automatic feeding system of material in roll, in versatile productive scenarios,there are different functional units participate the whole production line to gratify the purposed size, shape and pattern, our engineers grasp all of minutiae in attain the demanded plastic bags/sleeves/tubes, such as electric-oil heated level device, servo-motor driven transmission, pneumatic driven tension control, serigraph screen printing device, punching unit, multiple layers laminated bonding and tear-off cutting, waste material auto collecting system and auto positioning system and diagnosing system, thanks for our tech team with dedicated creative hard-working devote into procedures from initiation to finished machine at affordable price, let us start a joyful collaborative journey from your products,even a productive concept

Contact Us

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com