High Frequency PVC Tarpaulin Welding Machine of PVC Canvas_PVC Tents High Frequency Welding Machine in Tarpaulin/Canvas Welding

High Frequency PVC Tarpaulin Welding Machine

01: Application

High Frequency PVC Tarpaulin Welding Machine is designed specifically for production of small and large format tensile structures, membranes, tarpaulin, tents, oil booms, truck covers, swimming pool liners and covers, airline hangars, billboards, fast door, side curtains, PVC stretch ceiling, raincoat, inflatable toys, waterbed, large-scale advertising banner, awning, canopy, sun shading canvas, painting canvas, oil containment boom/fence, oil/water/gas tank, stretched ceiling, inflatable pool/boat, drift boat in welding, making, seaming the products made of PVC, PU, TPU coated fabric

High Frequency PVC Tarpaulin Welding Machine is equipped with special deep and wide trough behind the electrode for material storage and handling, machine also have optional smooth glide wheels for easy movement in-around welded fabric, or relocation to a design place in manufacturing hall

02: Parameter

| Name | High Frequency PVC Tarpaulin Welding Machine | ||||

| Model | KLR-5KWF | KLR-8KWF | KLR-12KWF | KLR-15KWF | KLR-25KWF |

| HF Power | 5kw | 8kw | 12kw | 15kw | 25kw |

| Input Power | 5KVA | 15KVA | 20KVA | 25KVA | 35KVA |

| Oscillation | 7T85RB | 7T69RB | E3130 | 8T85RB | 8T25RB |

| Max Pressure | 350kgs | 500kgs | 800kgs | 1000kgs | 1000kgs |

| Frequency | 24.12Mhz | 13.56Mhz | |||

| Rectifier | Silicon Diode | ||||

| Electrode gap | 100mm | ||||

| Active horn | 150mm | ||||

| Welding time | 0.01~9.99s adjustable | ||||

| Electrode size | 50*50*600 | 50*50*800 | 50*50*900 | 50*50*1000 | 50*50*1200 |

| Work table | 350*700 | 450*1050 | 450*1050 | 400*1150 | 400*1250 |

| Net Weight | 400kgs | 800kgs | 900kgs | 1200kgs | 1500kgs |

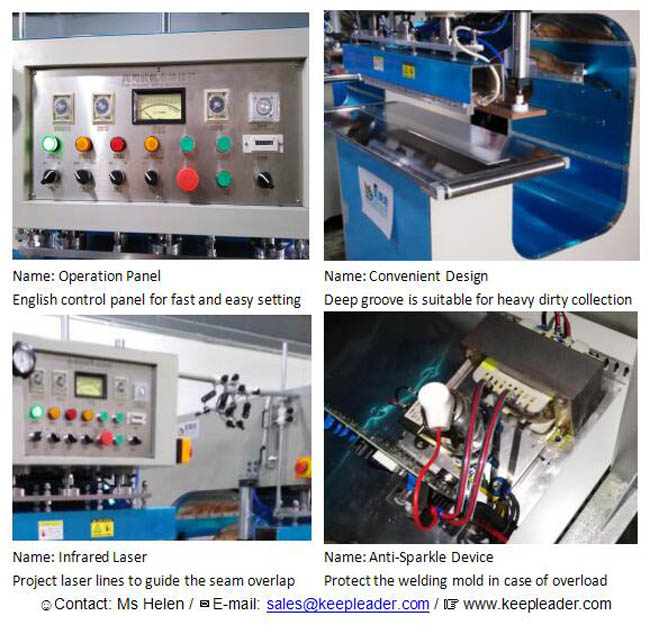

03: Highlights

Practical functionality with precision HF welding head

High efficiency HF weld cycles with 5kw~25kw output power

Sealing efficiency from 1kw: 40cm2 for standard PVC materials

Universal usage for PVC,PU,TPU,reinforced technical textiles

Easy material positioning with deep through behind electrode

G or C-frame rolled steel structure for excellent strength and work ergonomics

Key parts are imported and highly reliable

With big sized platen and working area, easy to set up and remove the dies

Sensitive anti-flash unit to protect machine and welding bar

Length,width and radian of welding area can be adjusted by welding electrode

Free space of 750mm behind the electrode is suitable for big size pass-by through

Infrared projector guide the overlap jointing line

European standard oscillation coaxial barrel is more reliable and stable in output

Precision HF tuning system generate high frequency circles in excellent joint effect

Single line or two lines continue welding, welding length can make as special need

04: Buying Guides

Advantages of High Frequency PVC Tarpaulin Welding Machine

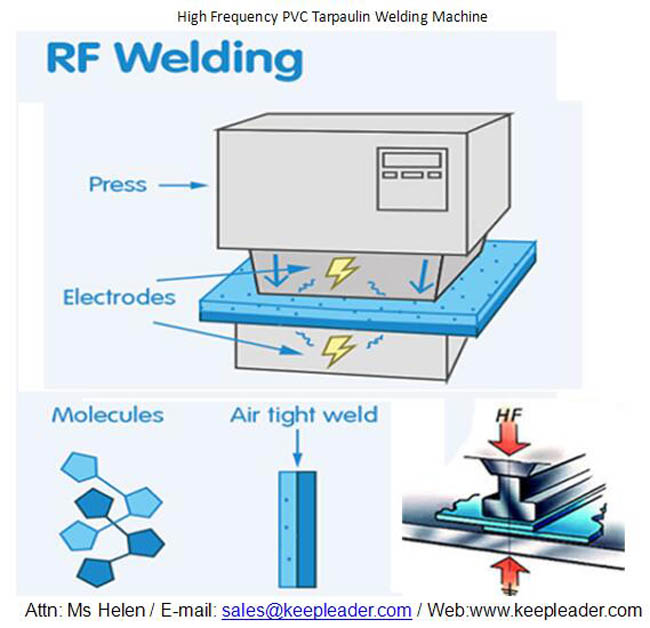

High frequency welding occurs from the inside out by using the material itself as a heat source, the heat is focused at the weld target so that the surrounding material does not have to be super-heated to arrive at a target temperature at the point

High frequency welding heat is generated only when the field is energized, once the generator cycles, the heat is turned off, this allows for greater control over the amount of energy that the material sees over the entire cycle, in addition, high frequency generated heat does not radiate off the die like on a heated die, this prevents heat-degradation of the material abutting the weld.

High frequency tooling usually run “cold”, this means that once the high frequency is turned off, the material stops being heated, but remains under pressure in this fashion it is possible to both instantly heat, weld, and cool the material under compression, more control over the weld results in more control over the resulting extrusion, thus increasing the weld strength

High Frequency PVC Tarpaulin Welding Machine is “clean” because the only material needed to produce an HF weld is the material itself, there are no adhesives or by-products involved in high frequency tarpaulin welding

High Frequency PVC Tarpaulin Welding Machine is optional of #1: Through depth #2: Size of Electrode & Table #3: Output power #4: Special Configuration #5: Components

High Frequency PVC Tarpaulin Welding Machine has practical functionalities from different customers’ feedback

High Frequency PVC Tarpaulin Welding Machine often used for PVC,PU, TPU Seam seaming, if you want weld PET,Nylon, the electrode need preheated function

Making the decision to purchase High Frequency PVC Tarpaulin Welding Machine for your manufacturing company is often a wise decision, but it is important that you find the right suplier for your high frequency PVC tarpaulin welding machine to get best results, keepleader can say with confidence that you can trust tarpaulin welding machine from keepleader, with over ten years under our valve-same supplying high-quality PVC tarpaulin welding machine to business, our reputation is one you can count on, let us help you find the right PVC tarpaulin welding machine for you business, we have a wide range of options to suit virtually any company’s needs and budget, contact us today

Attn:Ms Helen

E-mail:sales@keepleader.com

Cellphone/Wechat/Whatsapp:+86 1359041574

Tel:+86 755 84190358

Website: www.hfwelds.com / www.keepleader.com

High Frequency PVC Tarpaulin Welding Machine know as radio frequency (RF) welding or dielectric welding. Is the process of fusing tarpaulin together by applying radio frequency energy to the area to be joined, the resulting weld can be as strong as the original tarpaulin. High frequency welding replies on certain properties of the tarpaulin being welded to cause the generation of heat in a rapidly alternating electric field. This means that only certain tarpaulin can be welded using this technique. The process involves subjecting the parts to be joined to a high frequency (most often 27.12MHz and 13.56MHz) electromagnetic fields, which is normally applied between two metal bars/electrodes. These electrodes also act as pressure application during heating and cooling. The dynamic electric field causes the molecules in polar thermoplastics to oscillation. Depending on their geometry and dipole moment, these molecules may translate some of this oscillatory motion into thermal energy and cause heating of the tarpaulin. A measure of this interaction is the loss factor, which is temperature and frequency dependent.

PVC and polyurethanes are the most common thermoplastics to be welded by the high frequency process, it is possible to high frequency weld other polymers including nylon, PET, PETG, APET, EVA and some ABS resins, but special conditions are required, for example nylon and PET, are weldable if preheated welding electrodes/bars are used in addition to the high frequency power.

High frequency welding is generally not suitable for PTFE, Polycarbonate, polystyrene, polyethylene or polypropylene, however, due to the impending restrictions in the use of PVC, a special grade of polyolefin has been developed which does have the capability to be high frequency welded.

The primary function of high frequency PVC tarpaulin welding is to form a joint in two or more thickness of tarpaulin, tent, PVC/PU Coated fabric. A number of optional features exist. The welding tool can be engraved or profiled to give the entire welded area a decorative appearance or it can incorporate an embossing technique to place lettering, logos or decorative effects on the welded object. By incorporating a cutting/trimming/forming edge to the welding surface, the process can simultaneously weld and trim/cut/form a tarpaulin, the forming edge compresses the hot plastic sufficiently to allow the excess scrap material to be torn off, hence this process is often referred to as tear-seal welding.

A typical plastic welder consists of a high frequency generator (which creates the radio frequency current), a pneumatic press, an electrode that transfer the radio frequency current to the material that is being welded and welding bench that holds the material in place, high frequency PVC tarpaulin welding machine is radio frequency process in membrane structure seam sealing, the machine could also have a grounding bar that is often mounted behind the electrode, which leads the current back to the machine (grounding point). there are different types of plastic welders, the most common being tarpaulin machine, packaging machine and automatic machines.

By regulating the machine’s tuning, the field strength can be adjusted to the material being welded, when welding, the machine is surrounded by a radio frequency field that, if too strong, can be heat up the body somewhat. This is what the operator needs to be protected from. The strength of the radio frequency field also depends on the type of material being used. Generally, machines with visible open electrode (non-shielded) have stronger fields than machines with enclosed

When describing high frequency electromagnetic field, the field’s frequency is often mentioned, the permitted frequency for tarpaulin welding machine is 13.56MHz, 27.12MHz or 40.68MHz, the most popular industrial frequency for high frequency tarpaulin welding machine is 27.12MHz.

The radio frequency welding (High frequency welding) fields from a plastic welding machine spread out around the machine, but most often is only right next to the machine that the field is so strong that precautions need to be taken. The field’s strength decreases sharply with distance from the source. The strength of the field is given in two different measures: the electric field strength is measured in its per metre (V/M), and the magnetic field strength is measured in amperes per metre (A/m). both of these must be measured to get an idea of how strong the radio frequency/high frequency field is. The current that goes through you if you touch the equipment (contact current) and the current that goes through the body when welding (induced current) must be measured

Maximum permitted levels according to EU regulations

Average over 6 minutes

Electric field strength: 61v/m

Magnetic field strength: 0.16A/m

Induced current: 100 mA

Contact current: (not averaged): 40mA