HF PVC Welding Machine For Plastic Blister Paper Card Welding_Sealing oF Rotary PVC/PET Blister High Frequency Welding Machine

01:Parameter

| Model | KLR-5000S/AE | KLR-8000S/AE | KLR-10KW | KLR-15KW |

| Power | 5000W | 8000W | 10000W | 15000W |

| Power Supply | 380V 3P 50HZ | |||

| Frequency | 27.12MHz | |||

| Input power | 8KVA | 15KVA | 18KVA | 25KVA |

| Rectifier | SILICON DIODE | |||

| Oscillation tube | 7T85RB | 7T69RB | E3069 | 8T85RB |

| Max pressure | 350KG | 500KG | 800KG | 1000KG |

| Gap of electrodes | 200MM | |||

| Cylinder Stroke | 100MM | |||

| upper electrode | 200*350 MM | 400*600 MM | 500*700MM | 600*900MM |

| upper electrode | 400*600 | 600*800 MM | 600*800 | 600*900MM |

| Welding time | 0~10S Adjustable | |||

| Productivity | 4000 times / 8h | |||

| Net Weight | 280kgs | 330kgs | 360kgs | 500kgs |

| Dimension | 1*0.7*1.8 m | 1*0.8*1.9 m | 1*0.8*1.9 m | 2.5*2.1*2m |

02:Application

HF PVCwelding machine for Plastic Blister Paper Card Welding issemi-automatic turntable high frequency welding in PVC Blister sealing, PVCBlister sealing with paper card, is the basic and popular model in blister packaging, is also available for PET Packaging sealing without edge trimming,KEEPLEADER also offer the robot arm complied for automatic loading andunloading to save the labor cost and improve the productivity

03:Features

Arc suppressor: when sparks occur, the special electronic circuit on this machineworks automatically and cuts high frequency immediately to suppress arcs andminimize damage to electrodes and materials, alarm lamp also works simultaneously

Jamming prevention: Equipped with frequency stabilizer and high frequency magnetic suppressor,this device prevents leakage of electromagnetic radiation to avoid jammingother electric instruments such as televisions and radios etc

Safety device: When the current exceeds its limits, the overload relay functionsautomatically to protect oscillation tube and rectifier, frequency deviationcaused by disoperation is also prevented

Easily adjustable: Output power can be adjusted at the tuner according to electrodesize and material thickness, in addition, other control devices and specialelectrical circuit have cut down required welding time considerably to raisethe machine productivity

Adjustmentfor the distance on the machine head: Adjust the distance on the machine headif practical as the mold’s size and height are different, save working loadwhile processing accuracy can reach to 98%

HF PVC Welding Machine For Plastic Blister Paper Card Welding is 1: semi-auto 2: Turntable 3: 3~15kw 4: Customized Mold for Blister Packaging

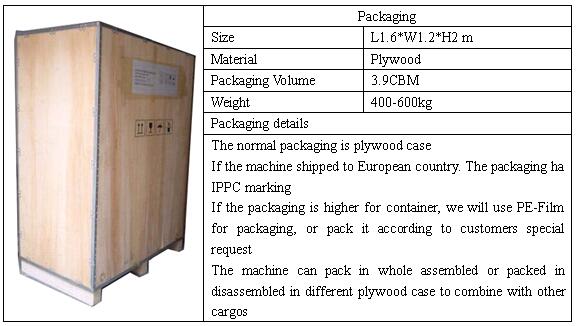

HF PVC Welding Machine For Plastic Blister Paper Card Welding has plywood case complied with oversea transportation in safety purpose, if you have special requirements, please confirm with us after your order

01: How to install and operate the machine?

Ourmachine is easy to install and convenient to operate, the machine comes with usermanual and train video, we also provide on-line support, the machine is usuallyinstalled in plywood case, which is helpful to avoid further installation anddebugging, only need resetting when you need replace the mold and welding,anyway, we will provide technical support

02: How can you ensure the machine quality?

Thecomponents of this machine are re-known supplier, which can source all over theworld, the machine is also built under strict quality controlling system, wetest its performance before delivery, each step of process is under yourcontrol and confirmation

03: How can we do if the machine has defectedaccessories?

HF PVC Welding Machine for Plastic BlisterPaper Card Welding has one-year warranty, during this time, keepleader willprovide free parts to replace, and provide technical solution to ensure themachine can work again

04: Howabout your warranty

We can provide 12 months free replace accessories. Meanwhile we willprovide 2-3 sets free accessories when you purchase the machine. If possible,our engineer can go to overseas for fix your machine