Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine_Suspended_Separated Head PVC Canvas Dielectric RF Sealer

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine

01: Application

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine is suitable for large canvas structure, large awing, large advertising canvas, high frequency dielectric bar welder can apply on thermoplastic application of membrane structure which contain polarity of the molecular structure, material which is applicable with this Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine are PVC,EVA,PU, PUR, TPU ,PVC Coated Fabric, when the electric power is applied onto the material, it caused vibration of the molecule which generate heat and enhance melting and joint of the material under the oscillation frequency of 27.12mhz, the melting exceptional causes from interior molecular flipping without any imposing of external heat, the welding part creates a stronger bond that the matrix material

02: Parameter

| Name | Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine | |||

| Model | KLR-8KWSF | KLR-12KWSF | KLR-15KWSF | KLR-25KWSF |

| HF Power | 8000W | 12000W | 15000W | 25000W |

| Input Power | 15KVA | 20KVA | 25KVA | 35KVA |

| Electric Connection | 220v.60hz or 380v,50hz more or less 20% Deviation | |||

| Upper Electrode Bar | 50*50*900 | 50*50*900mm | 50*50*1000 | 50*50*1000 |

| Low Electrode Plate | 600*1150 | 700*1150 | 700*1150 | 800*1250mm |

| Oscillation Frequency | 27.12mhz, more or less 6% deviation | |||

| Oscillation Tube | 7T69RB | E3130 | 8T85RB | 8T25RA |

| Applied Pressure Max | 500kgs | 800kgs | 1000kgs | 1500kgs |

| Electrode Interval Max | 200mm | |||

| Electrode bar travelling | 100mm | |||

| Welding Time | 0.01~9.99s | |||

| Welding Pressure | Air Compressed 0.5-0.7 MPa | |||

| Anti-Sparkle | NL-5557 High Sensitive Anti-Spark System | |||

| Rectifier | Silicon Diode | |||

| Cooling Model | Forced air cooling type | |||

| Driving System | Pneumatic Actuation | |||

| Working Tableside | Roller wheels | |||

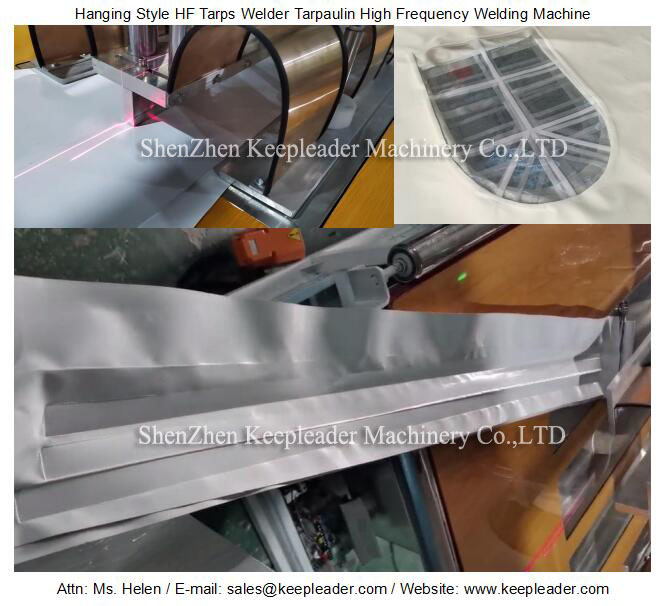

| Attachment | Laser Projector, Foot Pedal | |||

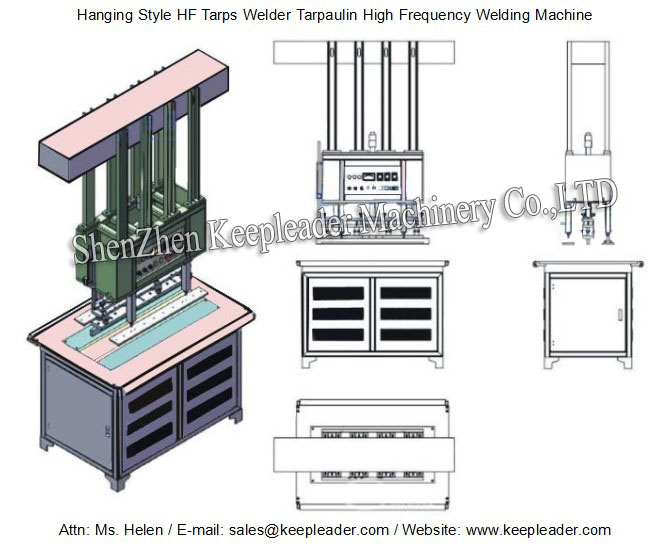

| Dimension | 1.6*1.4*0.9m | 1.6*1.4*0.9m | 2.5*1.7*2.3m | 2.5*1.7*2.3m |

| Net Weight | 800kgs | 900kgs | 1200kgs | 1400kgs |

03: Salient Character

Precise alignment that eliminates the risk of errors has improved the efficiency

Large working table is capable for large size alignment and alternate products

New design function-mode operates with high stability

High frequency output is very stable and welds smoothly

Equipped with ARC suppressor to protect the material and molds

Hanging head is capable of 360 degree alignment to process infinite material

Easy tuning and special protection circuit, the scalable output power ensure stable quality

Good shielding, No high frequency radiation, all the parameter pass inspection

The machine’s routine maintenance and diagnosis is very simple

Four sides of working table mounted ancillary roller to avoid scratch during alignment

Multiple access of emergency stopping system for convenient halt the machine

Indicators of power, working status, high frequency status enhance the visual monitoring

Flexible Holder supports quick changeover electrode bar for versatile sizes

Fitted out with the additional grounding electrode so as to protect the user against the increased level of HF non-ionizing radiation emitted by the machine

Automatic output power control system in order to increase the operator’s safety

04: Operation Steps

041: Preparation: the materials to be welded are prepared by cleaning and aligning the edges that need to be joined, this ensures proper fusion and a strong bond

042: Clamping: the prepared materials are hold together firmly using pneumatic system, this helps in maintaining alignment during the welding process

043: Application of high frequency energy: an electrode, typically made of aluminum, either or copper, is place on one side of the joint, while a grounding plate is placed on the other side, high frequency electric current is then passed through the electrode, creating an oscillating electromagnetic filed

044: Heating and melting: the high frequency electromagnetic field induces molecular oscillation and generate heat within thermoplastic material, this heat causes the material to soften and melt along the joint line.

045: Pressure and Fusion: Once the material reaches the desire melting point, pressure is applied to the joint using the pneumatic mechanism, the combination of heat and pressure ensures intimate contact between the melted surfaces, promoting fusion, the material cools and solidifies, forming a strong bond

046: Cooling and Finishing: After the welding process is completed, the joint is allowed to cool down, stabilizing the newly fuse area, depending on the application, additional steps such as trimming or finishing may be performed to achieve the desired final product

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine is ceiling suspended HF welding machine, hanging head enable the material handing all around the working table without any impediment, that can providing unrestricted space, good visibility and accessibility to the working area with high ergonomic characters permit precise performance of welding operation, this make this Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine suit for large material volumes, such as technical textile structure structures accordion doors, water tanks, tents, tensile and membrane structure, advertising billboards, oil-booms, water cisterns, pool-lines, etc, the high frequency generator, pneumatic press drive and electric power supply are perfectly integrated in robust, durable and stable system, Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine is stationary, but on clients’ demand, it can be mount on the rails, which makes it movable, keepleader, we can provide by numerous facilities for the work conform like lasers, personalized electrode, welding rod with different shapes and motives, easy electrode changing system, lighting projector and etc

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine is prevalent in large size textile, tarpaulin, canvas of seam sealing in industrial membrane structural construction, such as industrial canvas, PVC stretch ceiling, PVC tarpaulin, PVC tents, truck cover, PVC Canopy, PVC awning, PVC outdoor sunshade, film screen welding, advertising cloth welding, membrane structural welding, tent cloth welding, PVC Beach chair welding etc

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine is used in multiple industries that create straight and uniquely shaped products, from consistent straight welds like tarpaulins, high-speed rolling doors, and billboards to unique shapes such as oil booms, and billboards to unique shapes such as tent peaks, water cisterns and more, many companies require multiple technologies for different seams in their process, keepleader, we can integrated specified shaped and sized electrode bar to gratify versatile combination process with additional appendix

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine derives from high frequency welding, often abbreviated HF welding or RF welding, is a manufacturing process where two plastic parts are welded together using an electromagnetic field, the resulting join can be very strong, often close to the original strength of materials joined, in some scenario the weld can be even stronger that the original material, using a high frequency electromagnetic field, the material is heated and pressure added to melt and fuse two materials together, no outside heat is applied, instead the heat is generated within the material, during cooling under continued pressure, the materials are fused together and a weld has been created, this results in a very strong bond between the two parts

Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine

If you are interested in Hanging Style HF Tarps Welder Tarpaulin High Frequency Welding Machine for your tarpaulin welding needs, we have a wide variety of affordable and effective construction options to choose from at keepleader, why us, we have been in the RF welding business for over decades, proving the highest quality machines when it comes to RF sealing equipment and systems, we have a range of machines to meet both your budget and your goals for your business, we believe our combination of experience, flexible solutions and commitment to customer satisfaction is the key to our success and is why you will want to work with us new and in the future for your RF welding application, for more information n finding the right tarpaulin sealing machine for your business, contact us now

Contact Us

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com