Auto Walking High Frequency PVC Membrane Curtains Welding Machine for Sun Shading_PVC Curtain Cloth_Sun Screen Seam H.F Welding

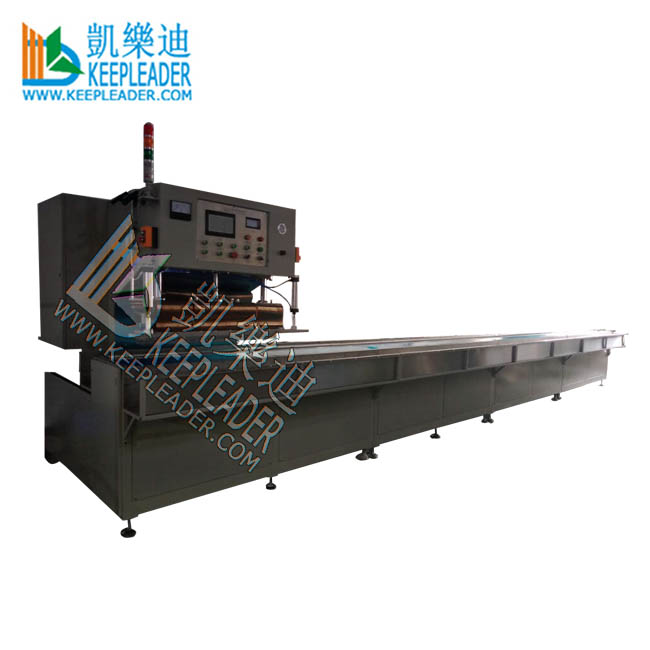

Auto Walking High Frequency PVC Membrane Curtains Welding Machine

01: Parameter

| Name | Auto Walking High Frequency PVC Membrane Curtains Welding | |

| Model | KLR-8KW-CB | KLR-15KW-CB |

| Output power | 8kw | 15kw |

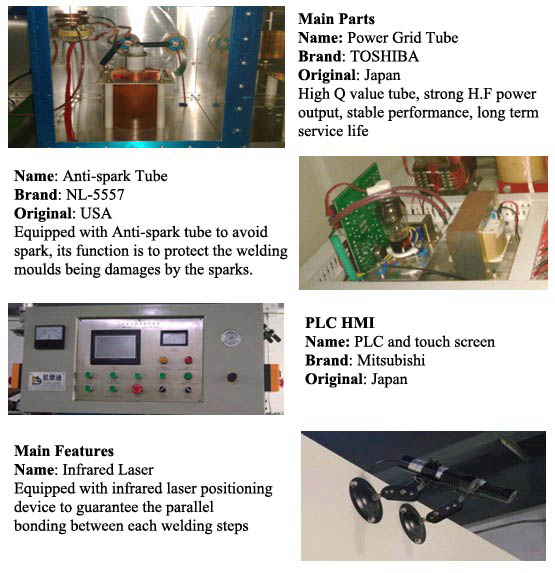

| Anti-spark system | PL-5557 High sensitive anti-spark system | |

| Voltage | 3P AN 380V 50~60hz or made as requested | |

| Frequency | 27.12mhz | |

| Input power | 15kva | 25kva |

| Rectifier | Silicone diode | |

| Oscillation Tube | 7T69RB | 8T85RB |

| Max pressure | 500kgs | 1000kgs |

| Electrode gap | 150mm | |

| Active horn | 150mm | |

| Upper electrode | 50*50*800mm | 50*50*900mm |

| Welding time | 0.01~9.99 adjustable | |

| Productivity | According to welding times and operator skills | |

02: Application

Auto Walking High Frequency PVC Membrane Curtains welding machine is especially designed for large format structural membranes curtains, sunshades, shading net, pool-liners, oil booms water cisterns, tarpaulin, tents, tensile structures, advertising billboards, spark protection cloth, truck tent, agricultural canvas, canopy, swimming pool covers and other PVC/PU Technical textiles, large PVC, automobile mats, inflatable boats, water beds, awning, canvas, fabric welding

03: Working principle

High Frequency PVC Membrane Curtains welding machine is using molecular vibration (friction heating) to provide uniform heating of PVC membrane Structural products, when the heat is transferred to the electrode (mold), the press can provide protection to the jointing surface, thus result in good welding performance, all materials which have polarity, such as soft PVC, Polyamide (PA), Polyester (PES), polyurethane (TPU), and some special TPO and some composite material can be welded with enough high frequency response or heating elements, as for non-frequency-respondent materials, such as textile, can be coated with high frequency-respondent material such as PU or PVC to enable high frequency welding, the other method is to apply a layer of hot melt glue on the non-frequency-respondent material, it can also provide a successful product welding in most cases

04: Characters

Auto walking style of welding head, continuously H.F welding

PLC touch screen and control panel of both systems can access the operation

Laser Guide projectors, projecting laser lines is visual guided for material positioning

Customized working tank dimension, electrode holder dimension and welding bar

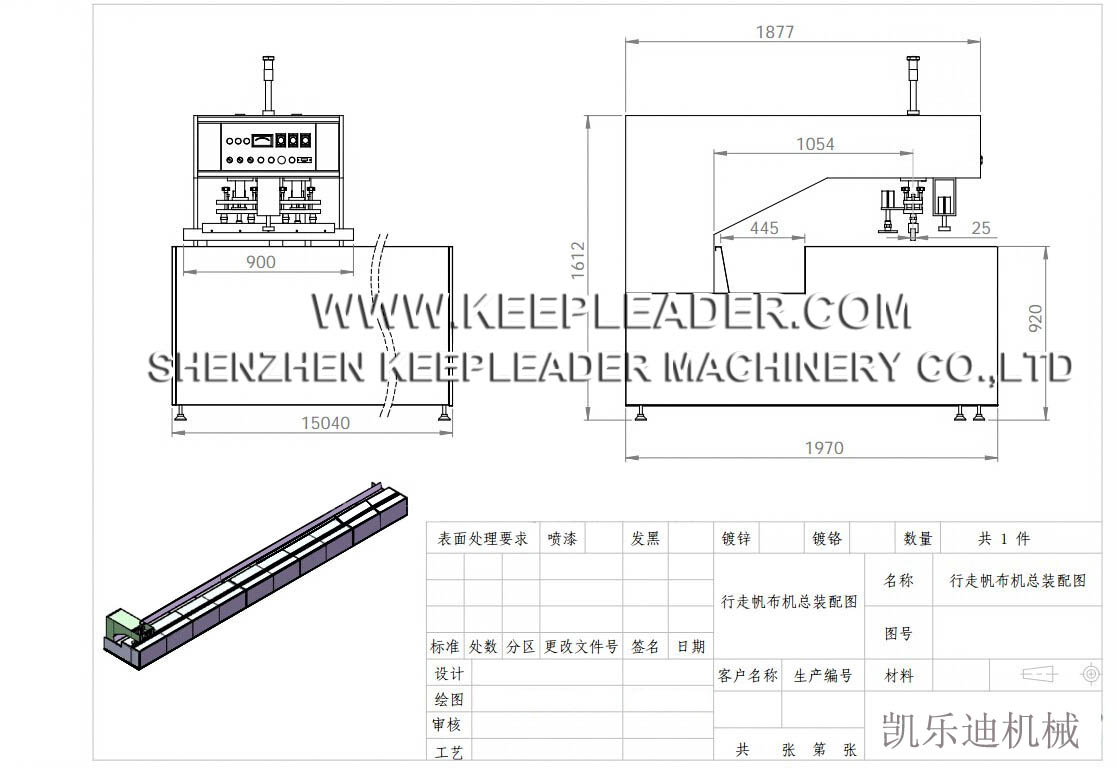

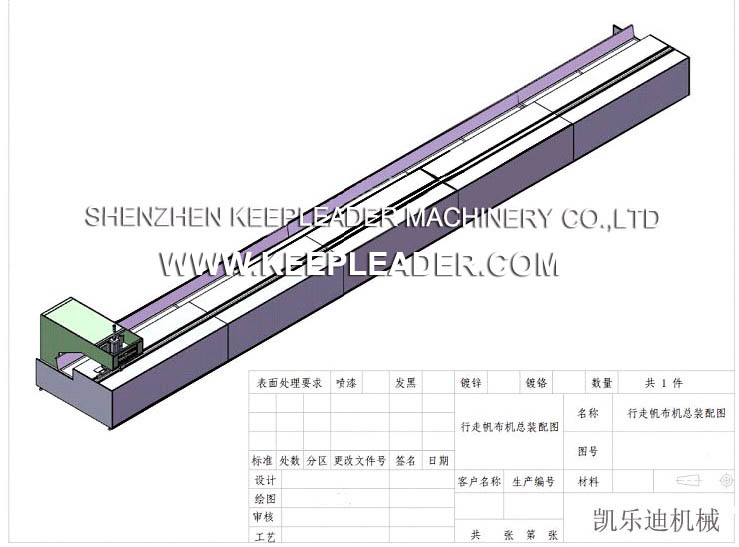

Standard working bench has length 6m, which can add sect by each 3m as demanding

Components adopt international standard, stable performance, easy to source to replace

European-standard square high frequency vibration box, stable and strong output

Sensitive arc suppressor built-in to protect the power circuit and welding mold

Equipped with special high precision ball bearing linear motion gear, controlled by high frequency inverter and glide-on railing to achieve a perfect continuous straight line seam

Single line or dual lines continue welding, its length made as requested

Can be used as a freestanding machine for welding production or as supplement to a large system

Front and two sides of welding head have start and emergency stop for convenient operation

05: Optional Features on request:

H.F Filter unit available

Auto-high frequency tuning technology

Precision straight bar welding up to 1500*50mm

Vacuum table available

Welding electrode temperature thermostat

Auto Walking High Frequency PVC Membrane Curtains Welding Machine has ♦1:customized table size, ♦2: H.F power ♦3: Optional Configurations made as demanding

Auto Walking High Frequency PVC Membrane Curtains Welding Machine also have other advanced components, if you cannot find your aimed parts, please confirm

Auto Walking High Frequency PVC Membrane Curtains Welding Machine has customized dimension of welding head, material groove and table length